The first iteration of heater flex, a thin, flexible circuit made of materials such as polyimide, was a significant improvement over the web of wires. Flexible circuits offered reduced mass and unique thermal properties that allowed Engineers to rethink their approach to electronics design. Engineers soon began to leverage the unique properties of flexible circuits for thermal management.

Modern Heater Flex

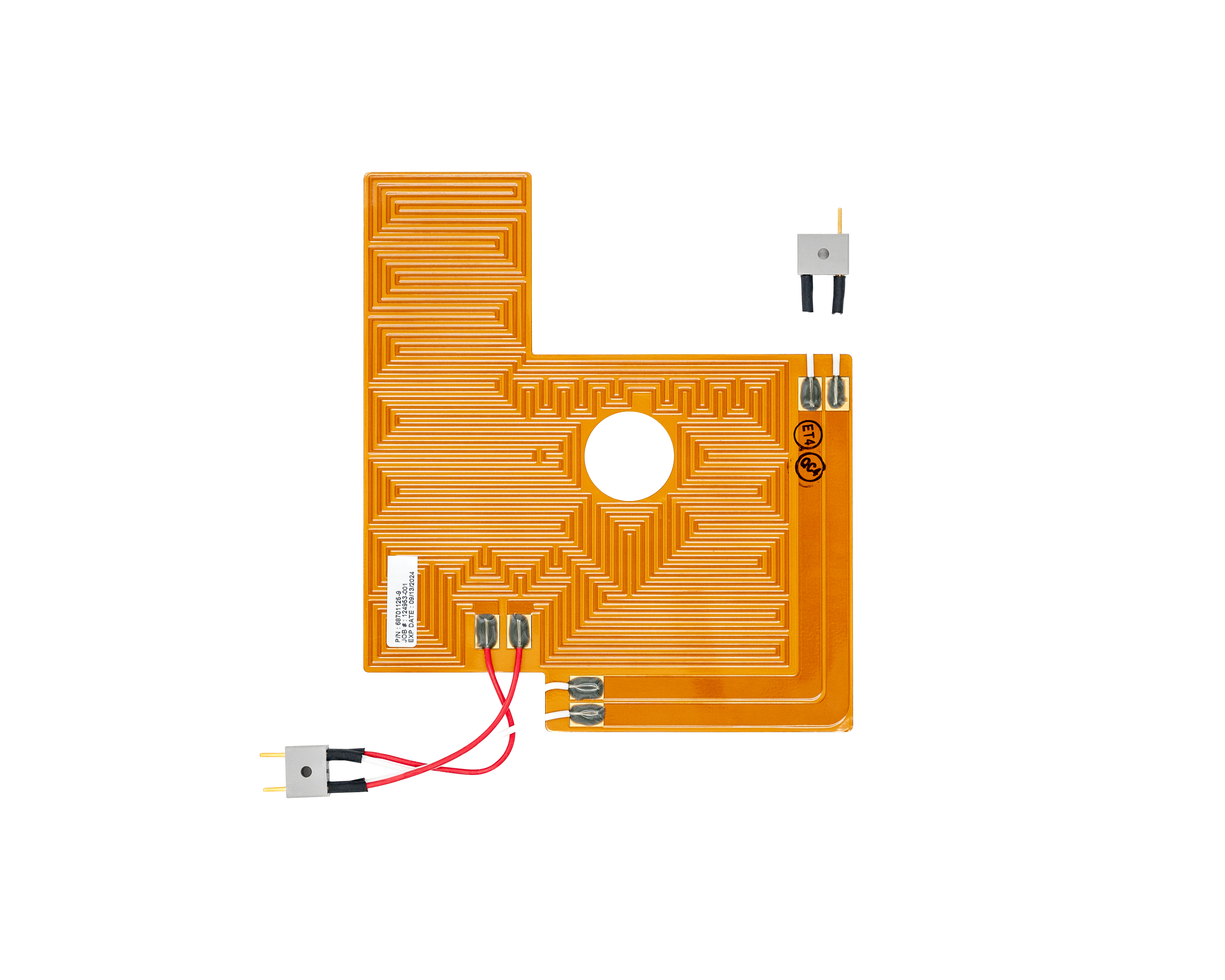

Fast forward to today, modern versions of heated flex circuits are designed to feature multiple layers and advanced materials. Some even incorporate thermal sensors that adjust heat distribution based on real-time needs! This level of sophistication ensures that your precious electronics, seat heaters, and heated clothes stay within their optimal temperature range, preventing overheating and extending their lifespan.

Heat Distribution:

Heat distribution is the process of uniform distribution of heat across the entire surface. This helps the heater to perform in the most optimal manner.

Techniques:

Heat Spreader: Copper foils and Aluminum foils are commonly used to spread the heat uniformly over the contact surface.

Heat Spreader: Copper foils and Aluminum foils are commonly used to spread the heat uniformly over the contact surface. - Circuit Routing: Proper routing and density of the circuit with even line width and spacing ensures that the circuit temperature is even.

- Material Selection: Choosing materials with high thermal conductivity, such as certain polyimide films would allow the heat to transfer through the dialectic material efficiently.

- Heater Foils: Typically, copper alloys such as Constantan, Cupro-nickel or Inconel are used to make heater circuitry. These foils do not change their resistivity with rise in temperature.

Heat Regulation:

Heat regulation is the process of controlling the temperature of the heated flex circuit to maintain a specific set point. This ensures consistent and reliable performance, especially in applications where precise temperature control is critical.

Techniques:

- Temperature Sensors: Devices that measure the temperature of the circuit and provide feedback to a control system.

- Thermistors: Temperature-sensitive resistors that change resistance with temperature, enabling precise temperature control.

- PID Controllers: Proportional-Integral-Derivative controllers that adjust the heating element’s power output based on the temperature error.

- Pulse Width Modulation (PWM): A technique to control the average power delivered to the heating element by rapidly switching it on and off.

The Benefits

So, how does this evolution of heater flex translate to technology?

- Hotter Performance: Modern heater flex heats up your devices operating at optimal temperatures.

- Heated Seats and Clothes: The circuit is strategically placed within the seat or clothing item to ensure constant warmth across the surface. This advanced circuitry allows for precise temperature adjustment, preventing over or underheating.

- Satellites: Heater flex circuits can be strategically placed to provide targeted heating, due to extreme temperature fluctuations in space, ensuring components function within their specified temperature ranges.

The Future is Bright

Researchers are constantly exploring new materials and configurations to push the boundaries of heat management. From keeping our smartphones regulated during intense gaming sessions to ensuring the optimal performance of heated gloves on a winter’s day, heater flex technology continues to shape our modern lives. As we look to the future, we can anticipate even more advanced solutions, to further improve heat management in electronics and other devices.

Check out our other post to learn more about the design and applications of heated flex circuits: Exploring the Design and Applications of Heated Flex Circuits | Flex Interconnect Technologies