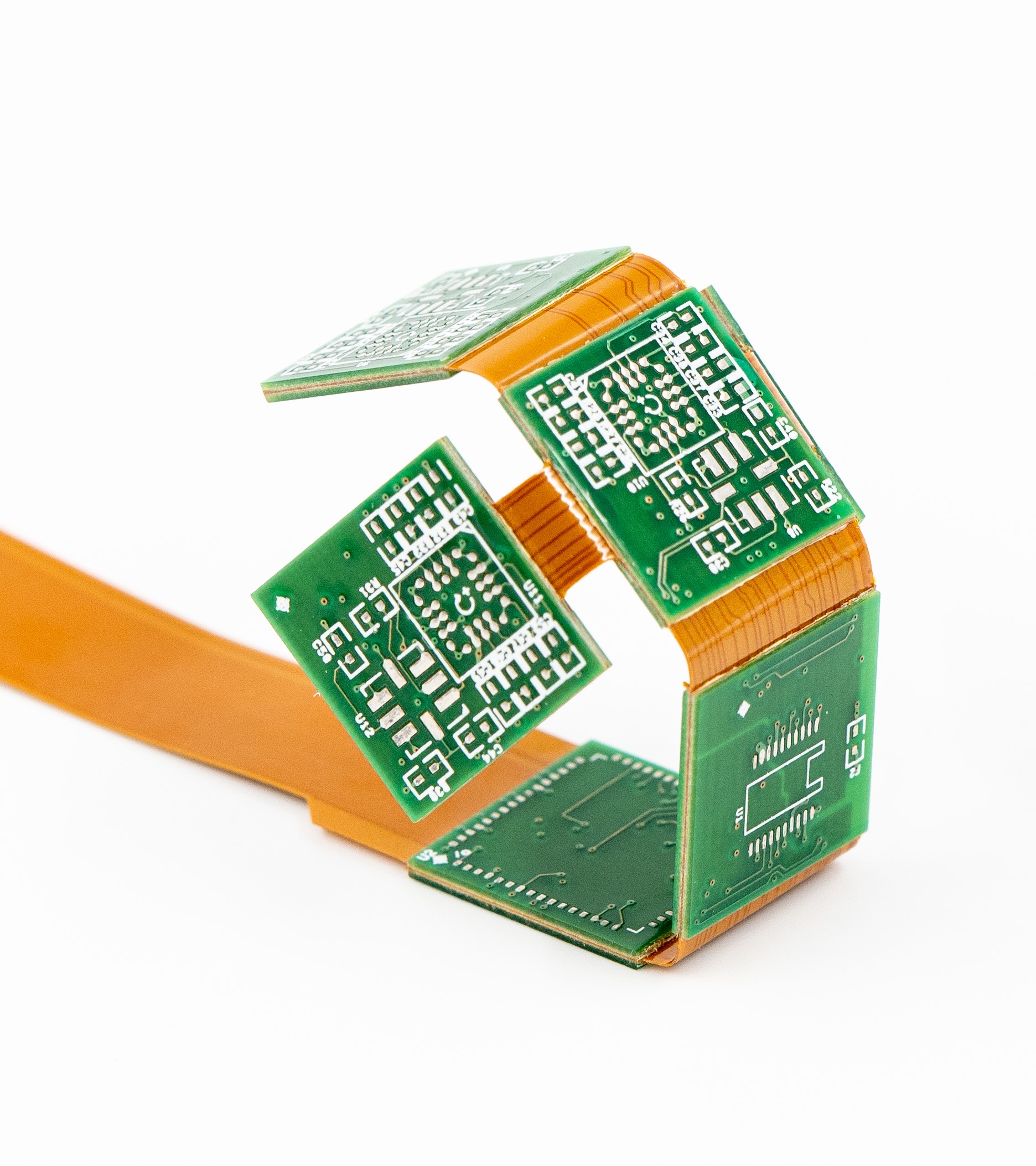

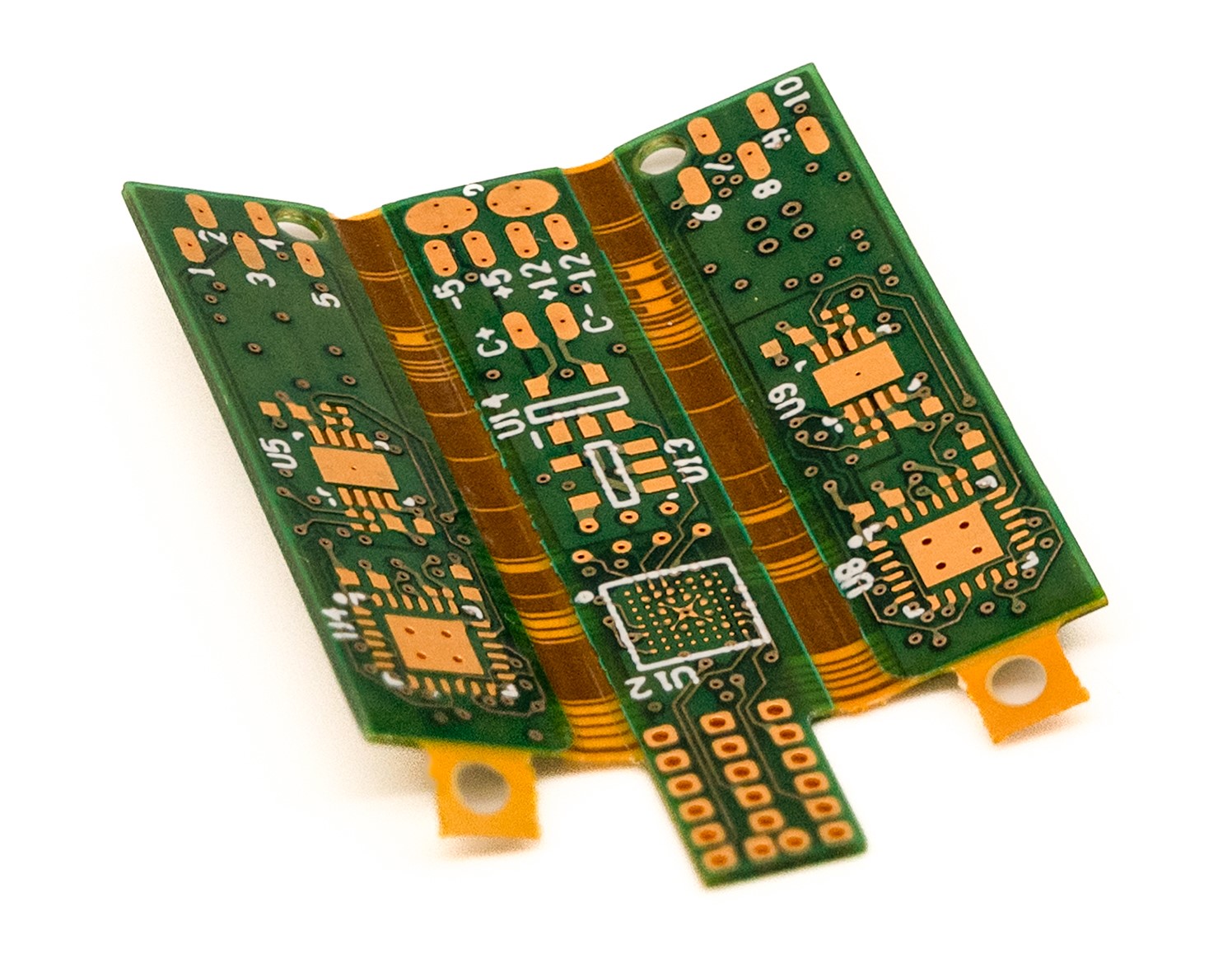

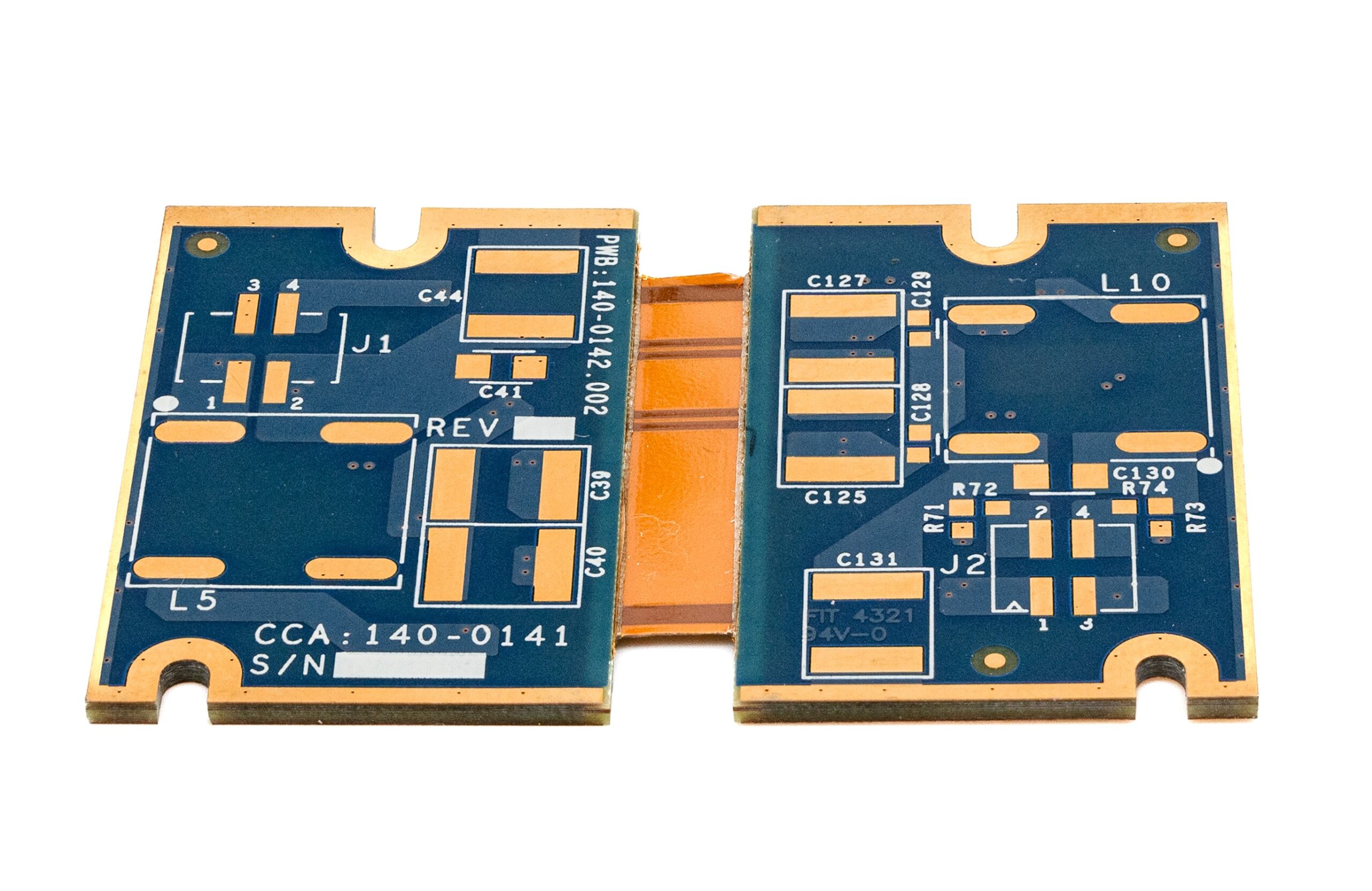

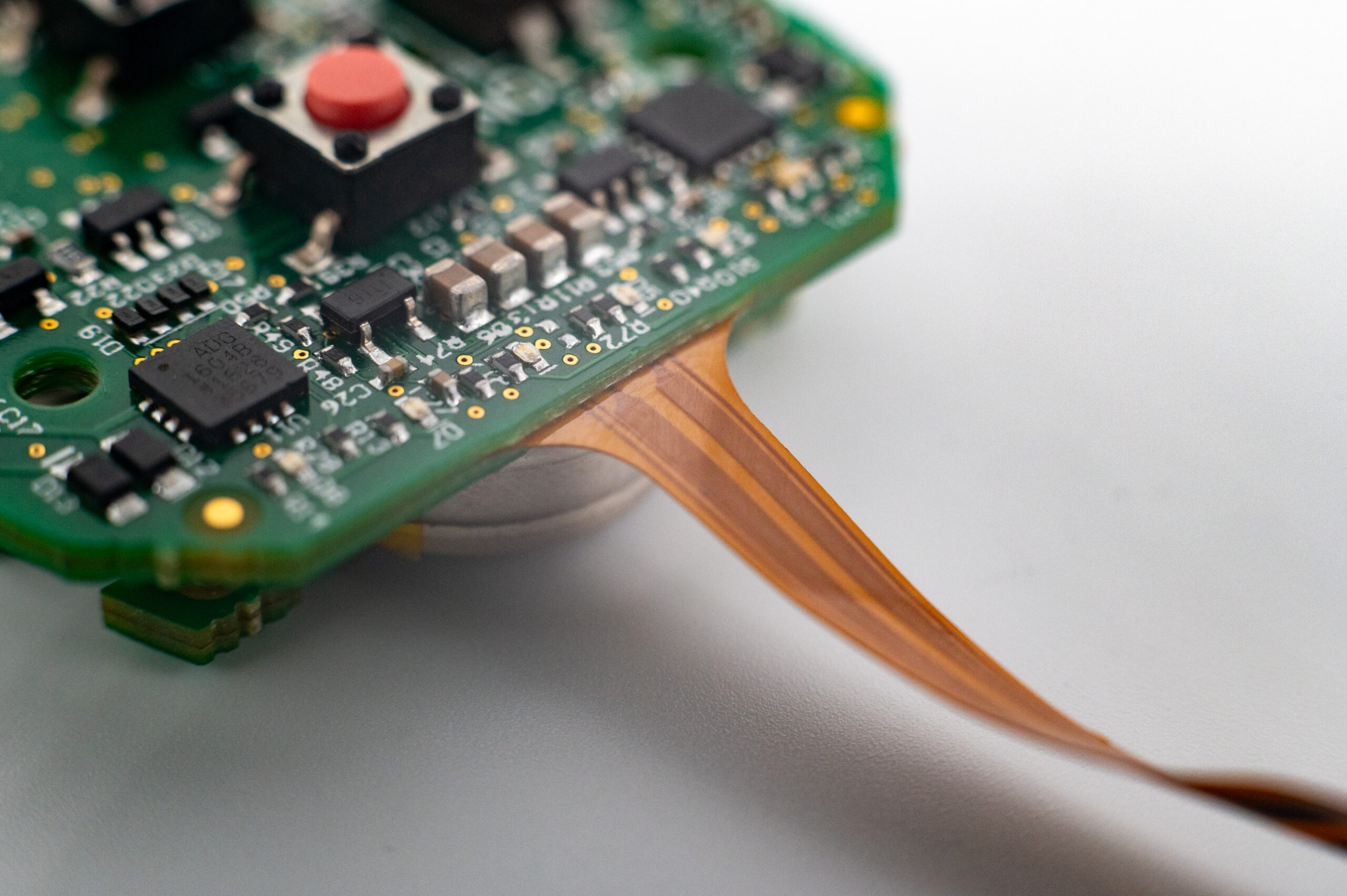

In the world of flexible electronics, every bend, twist, and connection plays a crucial role. When it comes to durability and performance, rigid-flex circuits (Advantages of Moving from Rigid to Rigid-Flex | Flex Interconnect Technologies (fit4flex.com))offer a unique advantage: the ability to combine rigid sections for stability with flexible areas for intricate designs. But with this flexibility comes a new challenge – choosing the right materials.

Understanding the Challenge

The combination of rigid and flexible materials in a single circuit introduces inherent stresses, especially at critical transition areas between the two material types. Stresses arise from differences in thermal expansion coefficients, varying material properties, and the mechanical demands of bending and flexing. If left unaddressed, these stresses can lead to reliability issues, compromising the functionality and lifespan of the final product.

The combination of rigid and flexible materials in a single circuit introduces inherent stresses, especially at critical transition areas between the two material types. Stresses arise from differences in thermal expansion coefficients, varying material properties, and the mechanical demands of bending and flexing. If left unaddressed, these stresses can lead to reliability issues, compromising the functionality and lifespan of the final product.

The Importance of Proper Material Selection

Selecting the right materials mitigates the risks associated with rigid-flex fabrication. High-performance grades of materials withstand the demanding conditions encountered during both fabrication and field operation. Failure to use suitable materials can result in process failures during manufacturing or, even worse, field failures that can halt operation and require costly repairs or recalls.

Key Material Properties to Consider

Several material properties play a crucial role in determining the suitability of materials for rigid-flex fabrication:

Glass Transition Temperature (Tg): The Tg indicates the temperature at which a material transitions from a rigid to a more flexible state. Choosing materials with an appropriate Tg ensures that they can withstand the thermal extremes encountered during soldering and thermal shock without compromising their integrity.

Glass Transition Temperature (Tg): The Tg indicates the temperature at which a material transitions from a rigid to a more flexible state. Choosing materials with an appropriate Tg ensures that they can withstand the thermal extremes encountered during soldering and thermal shock without compromising their integrity.

- FR-4: This is the most common material used in circuit boards, with a Tg around 170°C to 180°C. It offers a good balance of affordability, rigidity, and electrical performance for typical electronics operating at moderate temperatures.

- Polyimide (PI): When even higher thermal performance is needed, polyimide circuit boards are used. With a Tg exceeding 200°C, they excel in applications like aerospace, military, and downhole oil exploration, where extreme temperatures are encountered. However, their higher cost and more complex manufacturing process make them less common for everyday electronics.

Thermal Decomposition Temperature (Td): Td is always higher than Tg. For most circuit board materials, Td is likely well above 340°C, significantly exceeding typical operating temperatures and even soldering processes. Td represents the temperature at which a material begins to decompose. It’s imperative to select materials with a high Td to ensure stability and prevent degradation, particularly when exposed to elevated temperatures during manufacturing processes.

Thermal Decomposition Temperature (Td): Td is always higher than Tg. For most circuit board materials, Td is likely well above 340°C, significantly exceeding typical operating temperatures and even soldering processes. Td represents the temperature at which a material begins to decompose. It’s imperative to select materials with a high Td to ensure stability and prevent degradation, particularly when exposed to elevated temperatures during manufacturing processes.

- FR-4: Td is around 350°C to 400°C.

- Polyimide (PI): Polyimide offers a much higher Tg than FR-4. Following the trend, its Td can be reasonably assumed to be significantly higher as well. Estimates suggest a possible range exceeding 450°C for Td in Polyimide.

Coefficient of Thermal Expansion (CTE): The CTE measures the rate at which a material expands or contracts with changes in temperature. Matching the CTE of rigid and flex materials and copper foil minimizes the stresses induced by thermal cycling, reducing the risk of delamination or mechanical failure.

Coefficient of Thermal Expansion (CTE): The CTE measures the rate at which a material expands or contracts with changes in temperature. Matching the CTE of rigid and flex materials and copper foil minimizes the stresses induced by thermal cycling, reducing the risk of delamination or mechanical failure.

- FR-4: The most common material boasts a CTE of 14-17 ppm/°C in the plane of the board (X & Y direction). However, due to the glass fibers, the expansion is much higher (50-200 ppm/°C) in the Z-axis.

- Polyimide (PI): PI exhibits a CTE that varies depending on the specific type and processing. It is similar to FR-4 in both X, Y, and Z directions.

- Dimensional Stability: Materials with high dimensional stability undergo minimal size changes during processing, ensuring precise alignment and registration of layers. This property is critical for achieving tight tolerances in rigid-flex designs and avoiding issues such as warping or distortion.

- Bond Strength: Strong adhesion between layers is essential for ensuring the structural integrity of a rigid-flex PCB. Materials with excellent bond strength exhibit robust adhesion to copper, laminates, and other substrates, preventing separation or delamination under stress.

Overall, by prioritizing materials with high-performance characteristics manufacturers can mitigate risks and deliver robust, reliable products that meet the expectations of modern electronics applications.

Feel free to reach out with any questions or quote with us today:

Glass Transition Temperature (Tg): The Tg indicates the temperature at which a material transitions from a rigid to a more flexible state. Choosing materials with an appropriate Tg ensures that they can withstand the thermal extremes encountered during soldering and thermal shock without compromising their integrity.

Glass Transition Temperature (Tg): The Tg indicates the temperature at which a material transitions from a rigid to a more flexible state. Choosing materials with an appropriate Tg ensures that they can withstand the thermal extremes encountered during soldering and thermal shock without compromising their integrity.

Thermal Decomposition Temperature (Td): Td is always higher than Tg. For most circuit board materials, Td is likely well above 340°C, significantly exceeding typical operating temperatures and even soldering processes. Td represents the temperature at which a material begins to decompose. It’s imperative to select materials with a high Td to ensure stability and prevent degradation, particularly when exposed to elevated temperatures during manufacturing processes.

Thermal Decomposition Temperature (Td): Td is always higher than Tg. For most circuit board materials, Td is likely well above 340°C, significantly exceeding typical operating temperatures and even soldering processes. Td represents the temperature at which a material begins to decompose. It’s imperative to select materials with a high Td to ensure stability and prevent degradation, particularly when exposed to elevated temperatures during manufacturing processes.

Coefficient of Thermal Expansion (CTE): The CTE measures the rate at which a material expands or contracts with changes in temperature. Matching the CTE of rigid and flex materials and copper foil minimizes the stresses induced by thermal cycling, reducing the risk of delamination or mechanical failure.

Coefficient of Thermal Expansion (CTE): The CTE measures the rate at which a material expands or contracts with changes in temperature. Matching the CTE of rigid and flex materials and copper foil minimizes the stresses induced by thermal cycling, reducing the risk of delamination or mechanical failure.