Ready to streamline your electronic designs and optimize space utilization? Discover the power of rigid-flex circuit boards where multiple rigid boards and connectors are replaced with a single, robust solution. How can this innovative technology revolutionize your engineering projects?

Moving to rigid-flex circuits offers many advantages that revolutionize electronic design and manufacturing processes that include:

1. Streamlined Assembly

Consolidating multiple circuits into a single rigid-flex circuit simplifies assembly processes and reduces manufacturing complexity by

- Combining multiple boards and interconnects into a single rigid-flex board, creating fewer opportunities for error

- Resulting in faster production cycles and lower assembly cost

- Eliminating the need for additional cables and connectors

- Less SKU items to inventory and manage, thus lower system cost

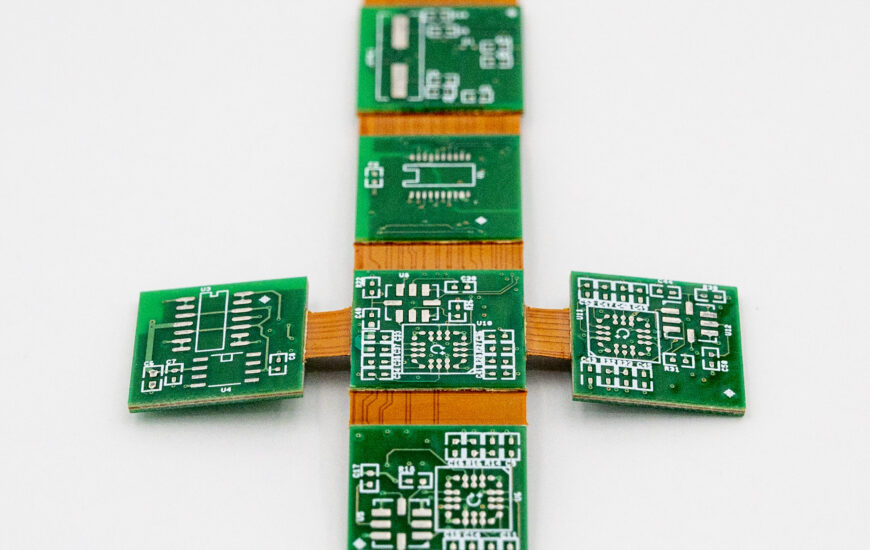

2. Space Optimization

Rigid-flex circuits allow for a seamless integration of rigid and flexible sections within a single board. This integration

- Eliminates connectors and cables, resulting in freeing up some space within your device

- Allows for compact designs and space-efficient products without compromising functionality

3. Enhanced Reliability

Rigid-flex circuit designs are well-suited for products subject to vibration, shock, or frequent movement because they minimize mechanical failures at solder joints and connectors by

- Reducing the number of interconnects

- Enhancing the overall reliability and longevity

- Eliminate the need for connectors between individual rigid boards

- Reducing risk, while increasing overall reliability

4. Weight Reduction

Rigid-flex circuits are ideal for weight-sensitive applications such as aerospace, automotive, and portable electronics. By minimizing weight without sacrificing structural integrity you can optimize performance, be energy efficient and meet demanding design requirements.

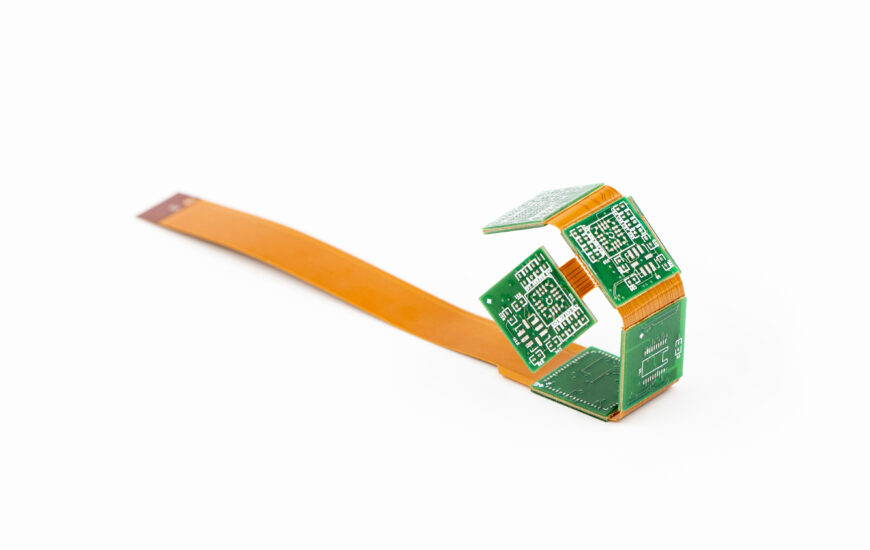

5. Design Flexibility

Rigid-flex circuits offer unmatched design versatility, enabling design engineers to

- Construct intricate, three-dimensional circuit solutions

- Create new opportunities for:

- Design

- Shrinking

- Form factor optimization

- Feature integration

6. Improved Thermal Management

Rigid-flex circuits offer greater thermal management thanks to the increased surface area for heat dissipation and the ability to incorporate heat sinks or thermal vias within the design. This allows you to

- Mitigate thermal issues more effectively

- Optimize your performance and reliability in high-temperature environments

- Allow better airflow in the enclosure

7. Cost Savings

While the initial investment in rigid-flex technology may be higher compared to traditional circuits, the following long-term cost savings can

- Reduce assembly time, by combining multiple circuits and interconnects into one rigid-flexible circuit solution

- Reduce circuits needed to source, manage, and assemble

- Reduce maintenance expenses over the product lifecycle

- Provide smaller and lighter mounts and housings

- Reduced logistical costs due to flexible circuits being smaller and lighter than traditional circuits. Costs such as:

- Shipping

- Warehousing

In summary, using rigid-flex circuits has benefits that go beyond economics; they promote sustainability and transform electrical design and production procedures, ultimately saving you both time and money.