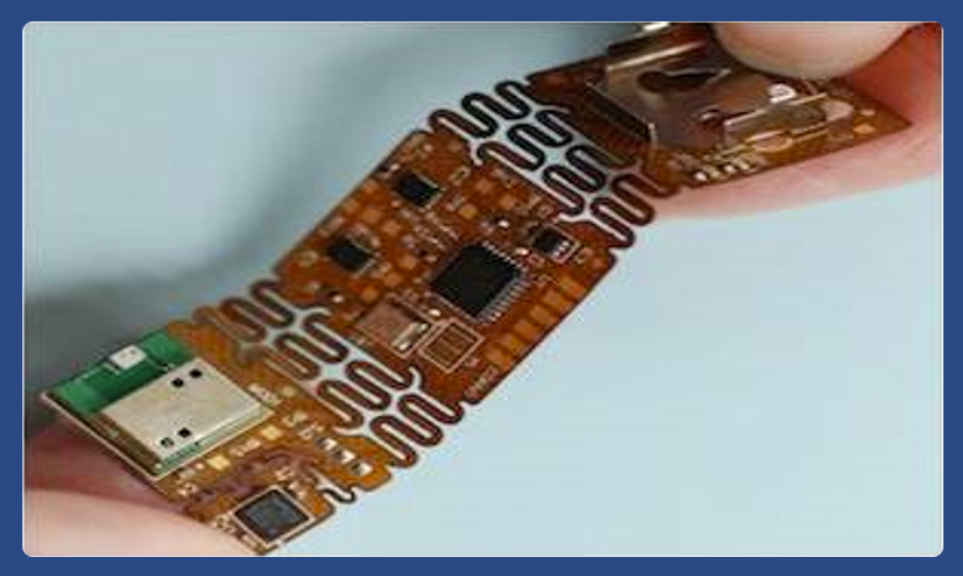

Flexible metal clad laminates are a specialized type of circuit board material designed to bend and flex without compromising performance. These materials are crucial in applications demanding flexibility, such as wearable electronics, medical devices, and automotive components.

The Benefits of Adhesive-Less Laminates

While traditional Flexible metal clad laminates often rely on adhesives to bond the copper foil to the base material, a preferred choice is an “adhesive-less” laminate. These laminates, like DuPont™ Pyralux AP®, offer several advantages:

High Thermal Properties: With a glass transition temperature (Tg) exceeding 220°C and a decomposition temperature (Td) surpassing 500°C, adhesive-less laminates excel in high-temperature environments.

High Thermal Properties: With a glass transition temperature (Tg) exceeding 220°C and a decomposition temperature (Td) surpassing 500°C, adhesive-less laminates excel in high-temperature environments. - Superior Dimensional Stability: A low coefficient of thermal expansion (CTE) of 18 ppm/°C ensures minimal dimensional changes with temperature fluctuations.

- Exceptional Bond Strength: The direct bond between copper and polyimide is exceptionally strong, rated at 8-10 lbs./in., providing durability and reliability.

- Outstanding Flexing Capability: Designed to withstand repeated bending, these laminates exhibit high resistance to cracking and foil fractures.

- Excellent Signal Integrity: The laminates as low loss tangent of 0.002-0.003 and Dk of 3.2, and can support high speed, 10 to 12 GHz applications.

Copper Foil Matters

The type of copper foil used in FCLs significantly impacts performance. A “wrought rolled annealed” copper foil, like IPC-4562 type W7, is preferred due to its:

- Ductility: Resists cracking during flexing.

- Elongation: Prevents foil fractures in plated through holes (PTHs) during thermal cycles.

Common Thicknesses

Flexible metal clad laminates are available in various thicknesses to accommodate different design requirements:

- Polyimide: 1, 2, 3, 4, 5, 6, 10 mils

- Copper: 1/8, ¼, 1/3, 1/2, 1, 2, 3 oz.

Thicker polyimide layers contribute to enhanced dimensional stability.

DuPont™ Pyralux AP®: The Adhesive-Less Leader

DuPont™ Pyralux AP® is a prime example of an adhesive-less copper clad laminate that meets the stringent requirements of IPC-4204/11. This product line offers the benefits outlined above, making it an ideal choice for demanding flexible circuit applications.

DuPont™ Pyralux AP® is a prime example of an adhesive-less copper clad laminate that meets the stringent requirements of IPC-4204/11. This product line offers the benefits outlined above, making it an ideal choice for demanding flexible circuit applications.