When holding a rigid board and a flex circuit side by side, it’s easy to assume that the rigid board will last longer. It feels thicker, heavier. Its corners offer the impression of precision. But that’s not necessarily the case.

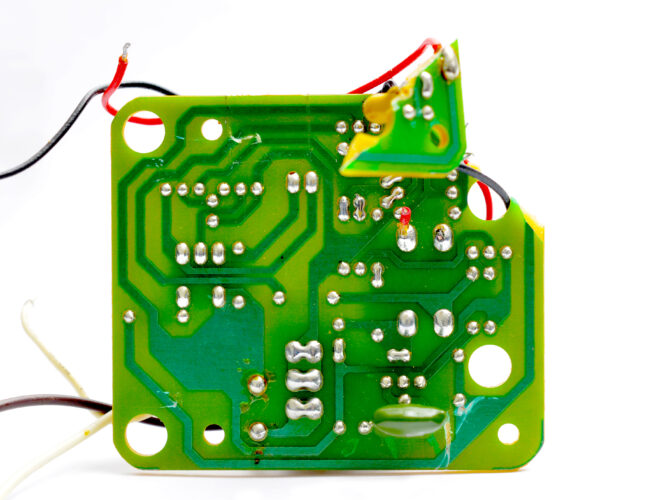

Rigid boards can be brittle. They are susceptible to damage from vibration or physical shock. Rigid boards usually require connections to other components, and those connections are also susceptible to failure, especially under harsh conditions.

To hedge against these types of failures, rigid boards often require extra engineering, features, or fixtures. For example, carefully engineered mounting fixtures within the final product can provide shock absorption.

On the other hand, by their nature flexible circuits handle movement well. And since the entire circuit is flexible, flex circuits better absorb shock and vibration. Depending on a flex circuit’s construction, an extra laminate layer can further help protect the circuit and its components.

Rigid-flex boards can offer the best of both worlds. Rigid flex boards help sure up connections between rigid circuits with integrated flexible circuit solutions, as opposed to requiring connectors or soldering between distinct components.

Manufacturing technology exists to ensure that your circuits last for years to come in their real-world application, regardless of which type of circuit you need. But durability affects cost. For many standard applications, a rigid board may offer a lower cost. But for more extreme applications, where vibration, shock, and extreme temperatures may be prevalent, it can be more affordable to select flexible circuitry rather than rigid boards that may require extras to meet the same performance requirements.

It’s important to share your real-world operating requirements with your manufacturers in order to receive solutions that fit your underlying business needs.

Comments are closed