We tend to like it when customers come to us as a last resort. It gives us the opportunity to show off our engineering skills. Here’s a design that challenged us in several ways, requiring us to extend our capabilities in order to meet the customer needs.

For this project, a medical device manufacturer came to us after several other US-based flex manufacturers passed on their project. Their design was complex, with several features and requirements that would prove challenging to manufacture:

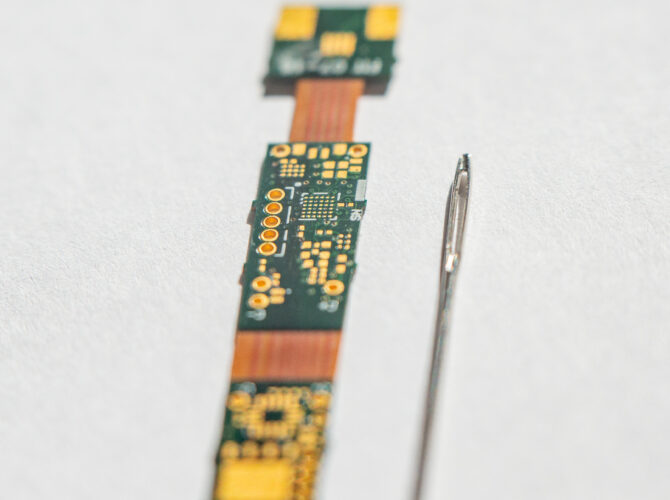

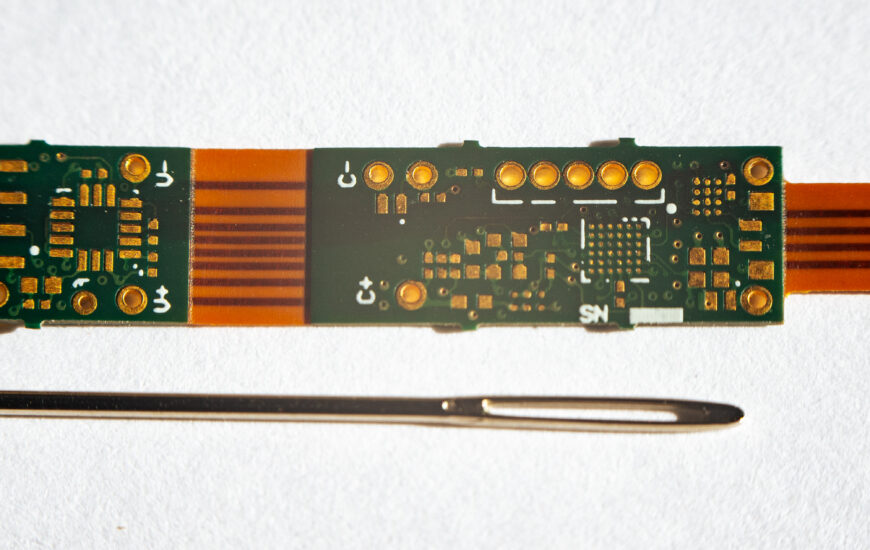

- Small size

- Rigid-flex

- 0.35mm BGA packages on the top and bottom

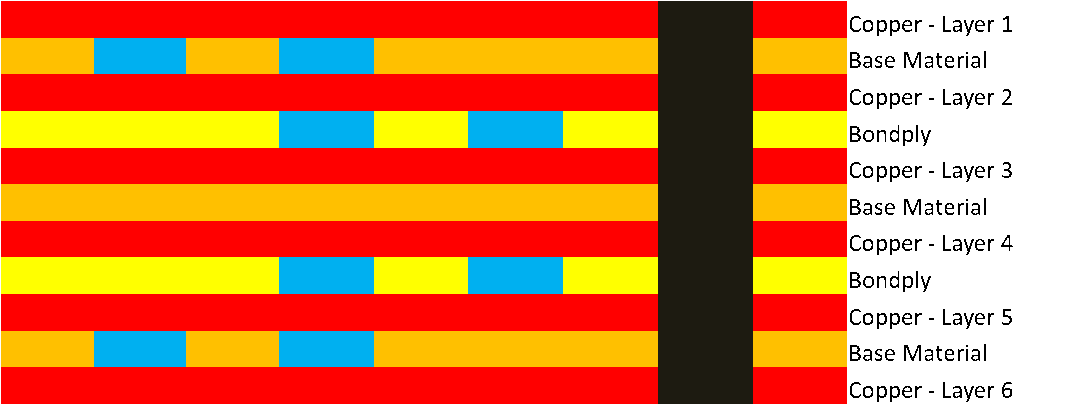

- 6 layers

- Stacked and staggered microvias on 10mil pads

- Several through holes

Manufacturing this design required an unconventional approach. Our solution began with all adhesiveless flex laminates, instead of rigid laminates and prepregs.

We also used a copper paste technology from a partner in Japan to form the microvia interconnects. This material ensured we’d meet the customer’s performance requirements, even at such a small scale.

In the end, the component worked, the customer was happy, and we were able to become one of their preferred vendors. What more could we ask for?