There’s a general consensus out there that flexible circuits cost more than rigid circuits. In fact, many engineers lean toward rigid PCBs in their projects due to the stigma of flexible alternatives carrying too high a price tag. But is there truth behind this commonly held belief?

Well, like most things in electronics design and fabrication, there’s not a simple answer.

Yes, if you have relatively simple requirements easily met through a rigid PCBA, that approach will almost always cost less than manufacturing a flexible solution. But rarely do circuit designs live in a vacuum. In fact, though the flex circuit itself may cost more, design engineers still opt for flexible circuits due to down-stream cost savings.

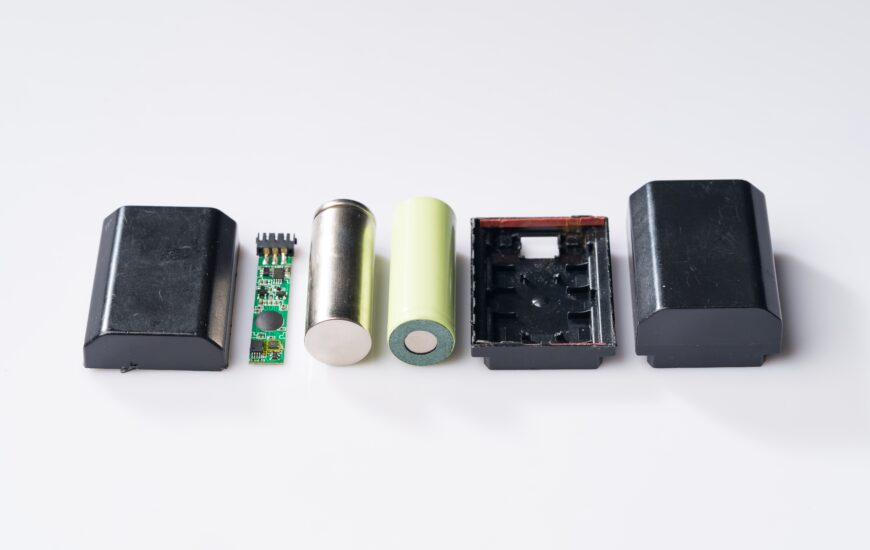

The above example shows the components of a modern camera battery. In this example, the rigid board met project requirements while fitting well within the existing dimensions of the final assembly. In this example, rigid was the better choice, keeping production cost down without compromising the design of the final product.

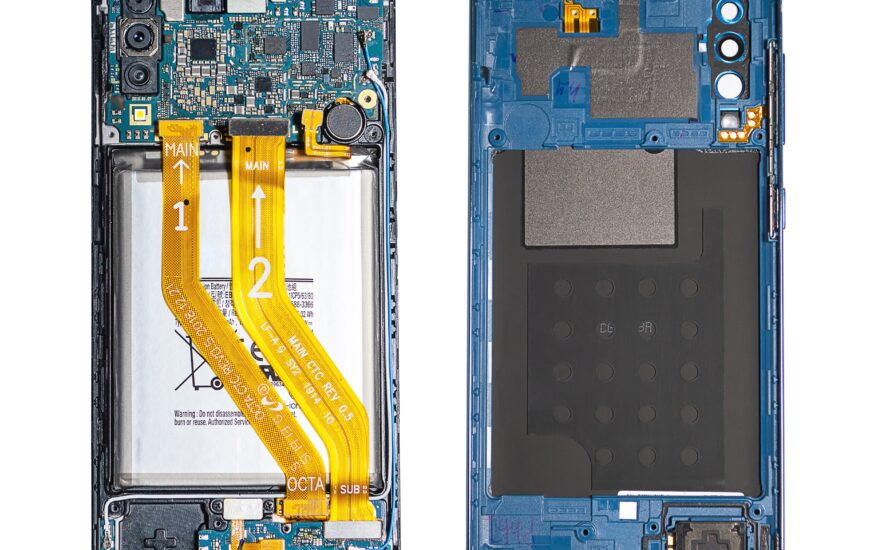

On the other hand, in our header image for this post you can see how flexible circuits were used to maintain the ergonomics of the digital camera. Opting for rigid boards here instead of flex would have undoubtedly added bulk to the finished product, and compromised the overall design of the camera.

Downstream Savings

Because they can bend, twist, and fold, flexible circuits allow for smaller enclosures and smaller finished products. Shaving off size and weight from the finished product often more than makes up for any cost premium of choosing a flexible circuit instead of a rigid board.

Flexible PCBs are manufactured to fit a device, while rigid PCBs require the device to be designed around the board. Often times, engineers find it more cost effective to fit a circuit into a device rather than build a device around a circuit.

If a rigid board costs $1.00 and its flex alternative costs $1.30, that doesn’t necessarily make the rigid board the smarter choice. If the flex circuit option results in a smaller finished product, that choice could easily save more than $0.30 in manufacturing, packaging, and shipping costs.

Combining Rigid and Flex Circuits

Modern electronics typically use a combination of both rigid and flexible PCBs. Design engineers choose to mount critical components, such as specialized integrated chips or power handling components, to rigid PCBs. In the finished device, flex circuitry such as ribbon connectors fit within the overall product design while connecting various rigid board elements.

What You Can Do

If you’re unsure about whether to solve a particular engineering problem with a flex or a rigid board, the best thing that you can do is to talk to your contract manufacturing partners. CMs like Flex Interconnect can help you best understand your options so that you can confidently make the right decision for your business needs.