Is it true that flex circuits can’t support the higher layer counts that rigid PCBs can? Well, not exactly…

In designing and manufacturing flexible circuits, there are multiple ways to accommodate high layer counts. Flex circuitry regularly supports stackups of 6, 8, 10, or even 12 layers. Rigid-flex constructions can go up to 40 layers or more!

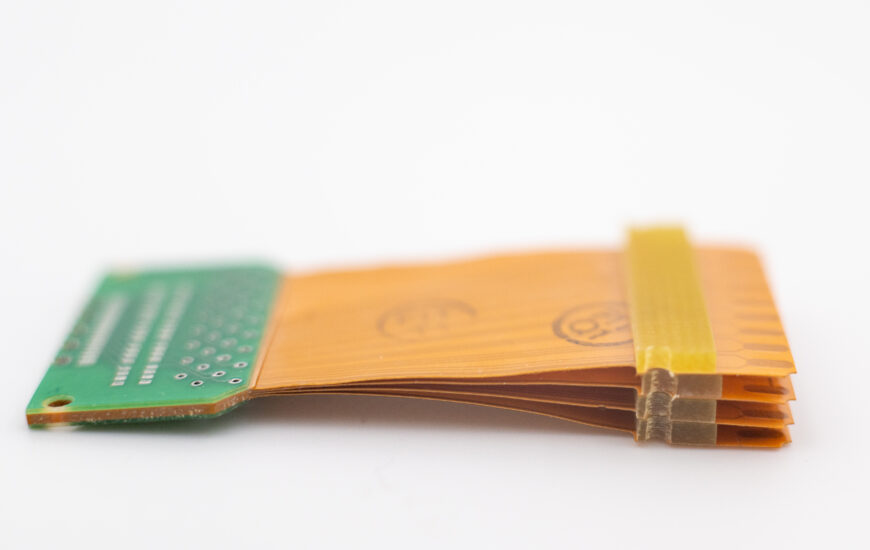

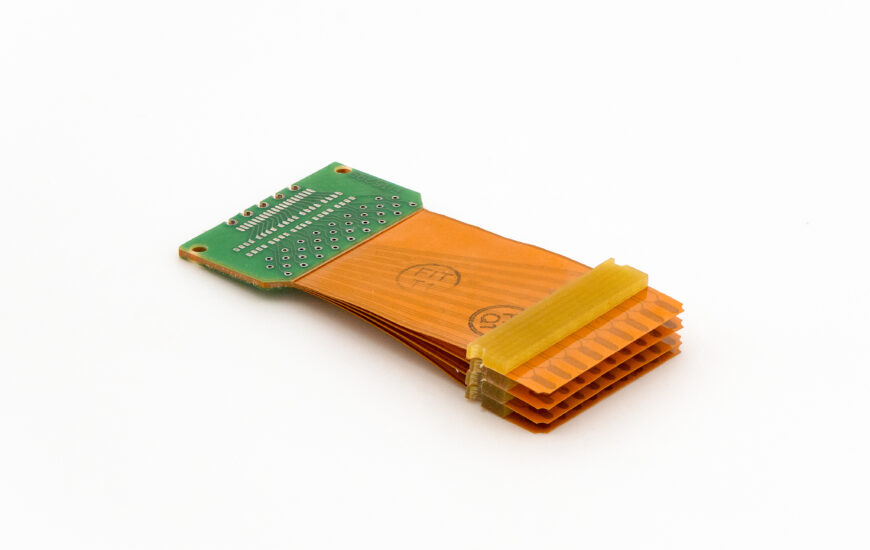

A common approach to supporting high layer counts in flexible circuits, “loose leaf” construction separates groups of layers into separate flex circuits. Whereas a single, eight-layer flexible circuit may prove difficult to bend, stacking four separate two-layer circuits can both meet the layer count requirement and offer mechanical flexibility.

The sample part in the image shows a rigid-flex part with a loose leaf feature. The loose leaf element includes four separate flex circuits, each with 18 separate connection points.

The entire part is about two inches long, with the flex feature roughly 1.5 inches long, 1 inch deep, and 1/4 inch thick, including all four loose leaf layers and the stiffeners used for secure mounting.

High layer counts are just one solution to underlying engineering challenges, such as power requirements, complexity, or tight geometries. Modern flex circuit manufacturing capabilities and materials offer other ways to solve for these same challenges. Consulting with your manufacturing partners early will help you and your team understand what options are available for your projects.